Hyundai Engineering has signed an MOU with Korea East-West Power for collaboration on hydrogen production and utilization projects using recycled plastic resources.

The agreement includes several projects such as recycling plastic resources for hydrogen production, hydrogen fuel cell power generation, hydrogen and ammonia fuel generation, green hydrogen production using renewable energy sources, and overseas business development for green hydrogen and ammonia.

Hyundai Engineering plans to supply Korea East-West Power with hydrogen from a new business focused on recycling plastic resources. They aim to build a recycled plastic recycling plant in Dangjin and produce 24,000 tons of hydrogen per year by 2026 using melting and gasification processes.

Hyundai Engineering has other ongoing projects related to recycling plastic resources, including a facility in the US that converts 450,000 tons of recycled plastic into petrochemical products annually and a project in Korea to produce high-value petrochemical products using 25,000 tons of recycled plastic.

According to an official from Hyundai Engineering, the company recognizes the global issue of plastic pollution and is committed to investing in research and development related to recycling plastic resources to meet growing social demand full-fledged.

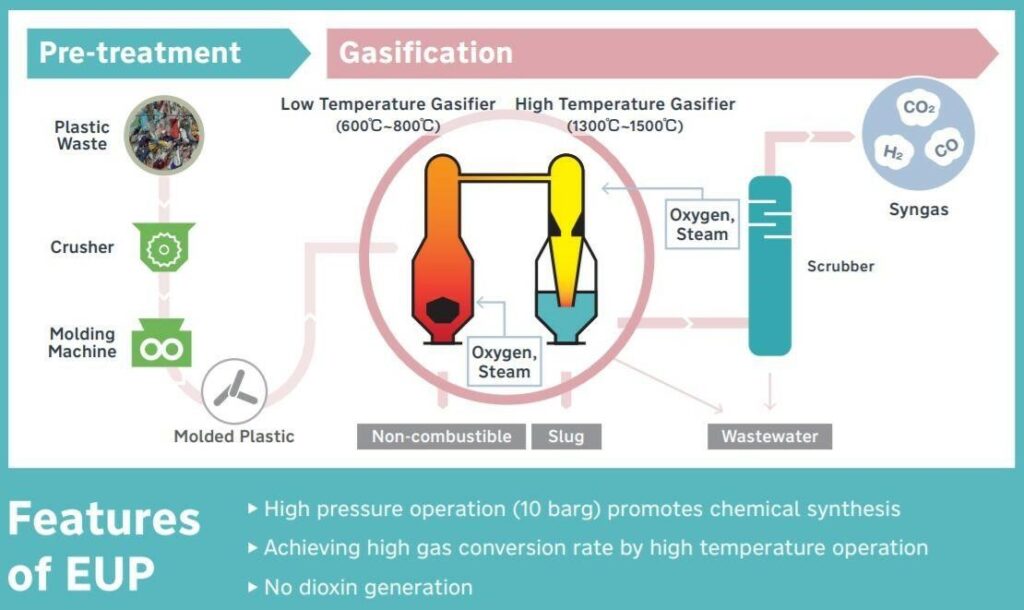

Ebara Ube Process Pressurized internally circulating fluidized-bed gasification system of EBARA ENVIRONMENTAL PLANT in Japan, which has LICENSE as a leading technology in this field, is likely to be introduced in Korea. Companies like Hyundai Engineering have bought LICENCE and are doing this in line with the national direction of the hydrogen economy.

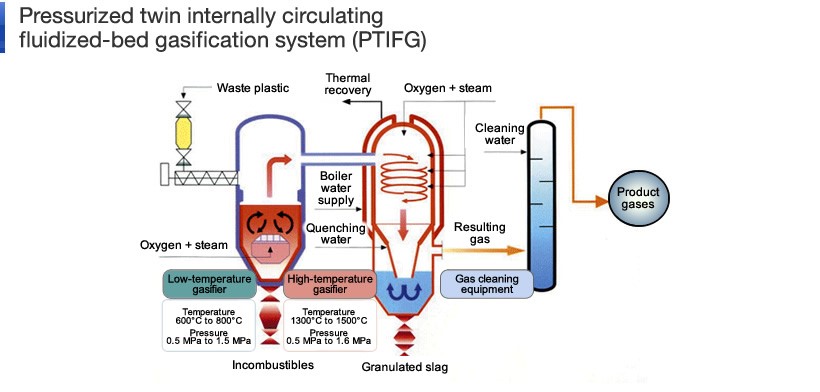

In accordance with the Korea National Hydrogen Economy Policy under the ESG initiative, more of the following technologies are being introduced in Korea and the industry is emerging. Below is the PTIFG technique Hyundai Engineering is trying to introduce.

Ebara Ube [ Patent name] Process Pressurized twin internally circulating fluidized-bed gasification system

This pressurized gasification technology combines our fluidized-bed low-temperature gasification furnace with Ube Industries’ high-temperature gasification furnace. It thermally decomposes plastic waste and other high-calorific value waste to produce a synthetic gas composed mainly of carbon monoxide and hydrogen. There are no concerns about the generation of dioxins following the high-temperature gasification. In addition, it allows fly ash to be recovered in the form of molten slag and reused as a cement material or for other purposes.

This technology thermally decomposes waste. It produces high-calorific value oil and gas composed chiefly of hydrocarbons from a wide variety of carbon resources in the form of solid waste, ranging from high-calorific value waste such as plastic waste to low-calorific value waste including household waste and biomass.

The oil and gas obtained can be used as raw materials in the chemical industry and as a source of energy that is an alternative to fossil fuels. This chemical recycling technology may reduce the amount of new chemical resources input into industries if it is incorporated into chemical industrial processes. If it is introduced in a process that consumes a massive amount of conventional fuels derived from fossil resources, the oil and gas obtained by the system will replace the traditional fuels to reduce the new consumption of fossil fuels. This feature makes the system suited for the reduction of carbon dioxide emissions.